Moving to a new home is an exciting fresh start, but it can also be a huge hassle. As you’re packing up your belongings, you’ll inevitably come across miscellaneous metal items you no longer need or want. Instead of just tossing them out, why not make some extra cash by selling them for scrap? At Action Metals Recyclers, we pay top dollar for all sorts of valuable scrap metals in Dallas.

Here’s a look at some of the top things you can sell for scrap during your next Dallas move.

Old Pots, Pans, and Kitchen Utensils

When it comes to kitchen items made of aluminum or stainless steel, don’t just throw them out – recycle them! Scratched non-stick pans, dented pots, chipped baking trays, and bent utensils may have no use to you anymore, but they can be melted down and repurposed into new metal products.

As you’re cleaning out your kitchen cabinets, set aside anything metal that’s too worn to keep using. Then before your move, stop by our Dallas scrap metal recycling facility to sell your steel scraps!

Large Appliances

You probably don’t want to move that old fridge, stove, dishwasher, or washing machine to your new place. These large appliances contain a significant amount of valuable steel and other metals in their frames, doors, coils, and more. Have them picked up for scrap rather than leaving them on the curb!

Odds and Ends from the Garage

Over the years, you’ve likely accumulated quite the collection of old tools, machine parts, lawn equipment, bicycles, grills, and sporting goods out in the garage or shed. Anything predominantly made of steel or aluminum can be sold for scrap metal recycling.

As you’re cleaning out the garage for your move, set aside non-working power tools, rusty shovels and rakes, busted lawn mowers, bent basketball hoops, and more.

That Junker in the Driveway

Have an old beater car, truck, or van that’s been sitting around collecting dust? Now’s the perfect time to finally get rid of it! Vehicles contain a huge amount of steel that can be melted down and repurposed into new metal products. Cars also have smaller amounts of valuable metals like aluminum, copper wiring, and platinum from the catalytic converter. We’ll take your junker off your hands and pay you the best rates in Dallas for the scrap metal.

Miscellaneous Renovation Leftovers

If you’ve done any home renovation projects like re-roofing, updating bathrooms or kitchens, or building an addition, chances are you have scrap metal leftovers tucked away in the basement or garage. Buckets of old nails and screws, metal piping, wiring, sinks, gutters, ductwork, and roofing materials can all be recycled for cash before you move out.

Recycle Your Scrap for Cash with Action Metals Recyclers

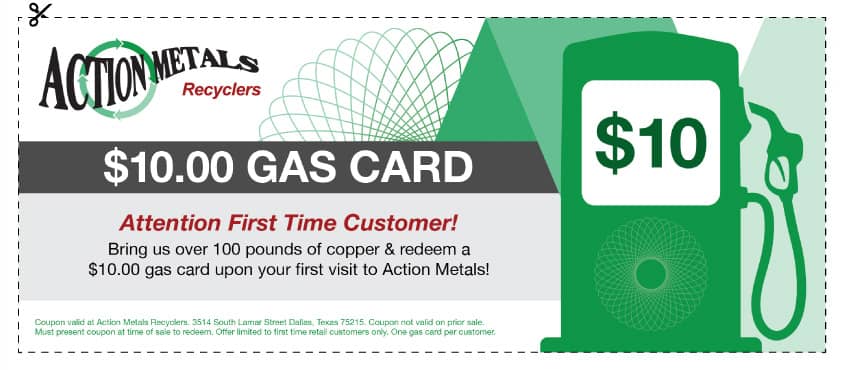

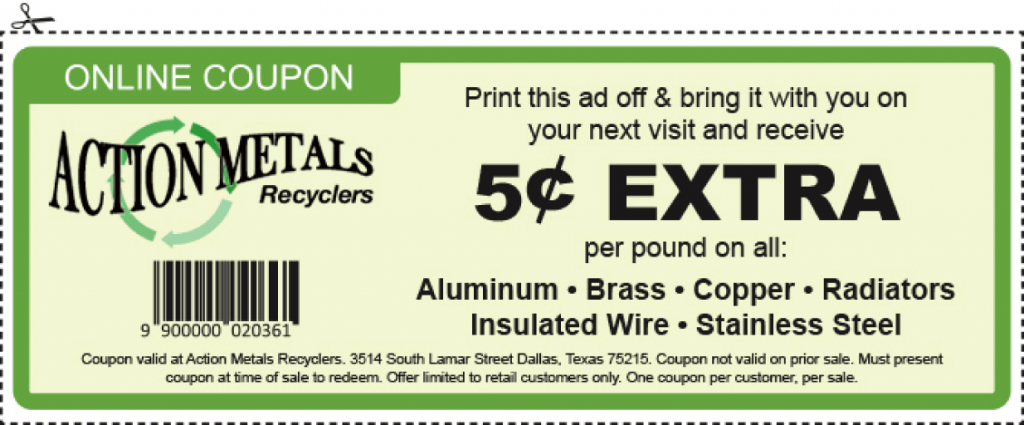

Don’t leave money on the table when you move! Bring all of your unwanted metal items to Action Metals Recyclers in Dallas, and we’ll pay you top dollar based on weight and material type. We accept ferrous metals like steel as well as non-ferrous metals including aluminum, copper, brass, and more.

Our convenient location and flexible hours make it easy to drop off your scrap metal any time.

Whether it’s an old grill, some bent bike frames, or the kitchen pots and pans you’ve had forever, we’ll make sure your unwanted metal goods get repurposed responsibly instead of ending up in a landfill.

Decluttering and getting cash for your scrap metal has never been easier than with Action Metals Recyclers. Contact us today to learn more about our services.