Do you have old, broken, or unused appliances cluttering your garage or basement? Before you toss them in the trash, consider the valuable metals hiding within them. Recycling metal from household appliances not only helps reduce waste and conserve resources but can also put some cash in your pocket.

Let’s explore the process and discover how you can contribute to a sustainable future.

Why Recycle Appliances?

Household appliances are treasure troves of recyclable metals. The average appliance contains a significant amount of steel, aluminum, copper, and sometimes even brass. Recycling these materials:

- Reduces Waste: Keeps large appliances out of landfills, conserving valuable space.

- Conserves Resources: Decreases the demand for mining new metals, reducing energy consumption and pollution.

- Economic Benefits: Some recycling centers offer payment for scrap metal.

- Environmental Stewardship: Minimizes the environmental impact associated with manufacturing new appliances.

Step-by-Step Guide to Recycling Appliances

Identify Recyclable Metals

- Steel: Found in appliance frames, bodies, and internal components.

- Aluminum: Used in motors, wiring, and trim pieces.

- Copper: Present in wiring, motors, and tubing.

- Brass: Occasionally found in valves and fittings.

Prepare Appliances for Recycling

- Unplug and Disconnect: Ensure all appliances are safely disconnected from power sources and any water or gas lines.

- Remove Hazardous Materials: If dealing with refrigerators or air conditioners, it’s crucial to have a professional remove harmful refrigerants before recycling.

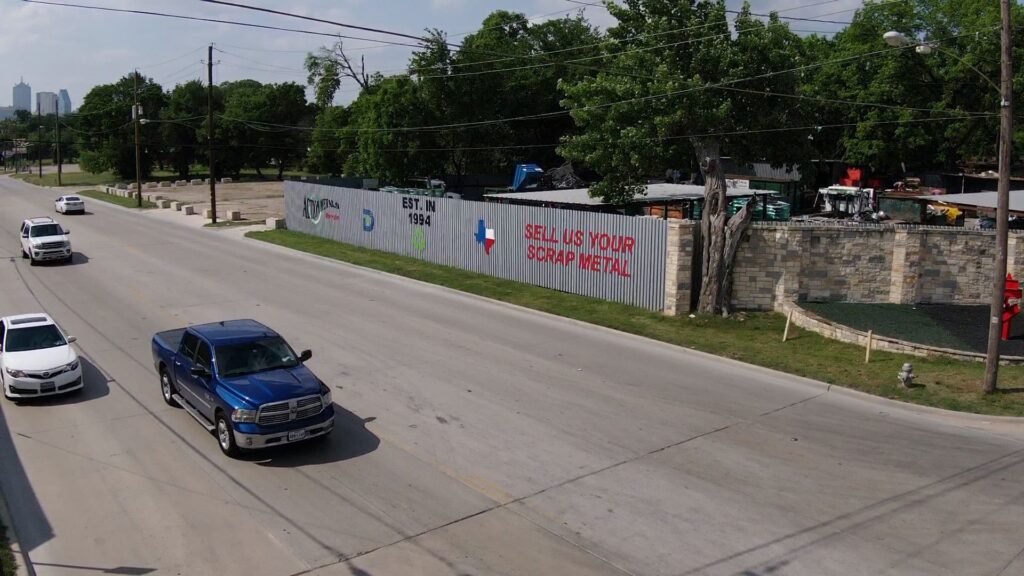

Find a Recycling Center

- Search Online: Look for local recycling centers or scrap yards that accept appliances.

- Check with Your Municipality: Your city or county may have designated drop-off locations or special pick-up services.

Transport and Drop Off

- Arrange Transportation: Depending on the appliance size, you might need a truck or trailer for transport. Some recycling centers offer pick-up services for a fee.

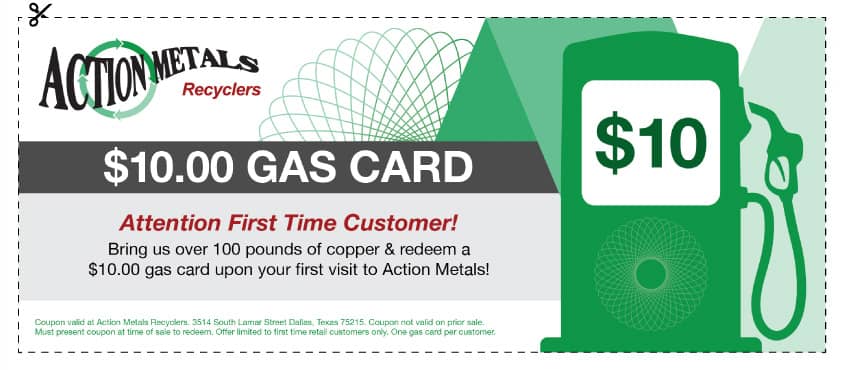

- Get Paid: Many scrap yards pay for scrap metal based on its weight and type. Be sure to inquire about their pricing structure.

Important Considerations

- Safety First: Always prioritize safety when handling appliances. If you’re unsure about disassembling or moving an appliance, seek professional assistance.

- Environmental Impact: Recycling appliances significantly reduces their environmental footprint. By choosing to recycle, you’re actively contributing to a cleaner, greener planet.

Frequently Asked Questions (FAQ)

Q: Where can I recycle appliances?

A: You can find local recycling centers and scrap yards that accept appliances by searching online or checking with your municipality. Many communities have designated drop-off locations or offer special pick-up services.

Q: Is it worth recycling appliances?

A: Absolutely! Recycling appliances not only helps the environment but can also be financially rewarding. Many recycling centers offer payment for scrap metal based on its weight and type.

Clean Up and Recycle With Action Metals

Recycling metal from household appliances is a simple yet impactful way to make a difference. By following these steps, you’re not only decluttering your space but also contributing to a circular economy and a sustainable future. So, the next time you have an old appliance, don’t let those valuable metals go to waste – recycle them and give them a new life! Contact Action Metals today to learn more about our recycling services.