Industrial recycling may be something your manufacturing plant has yet to think about prior to this point. However, this process is something that offers a number of benefits for the operation of your business, your company reputation, and your annual profits.

This subcategory of recycling involves taking the waste that’s generated from the processes that go on at your plant and ensuring that it’s going to go on to be used for something else. This is a much more eco-friendlier option than throwing away your scrap.

Here are some of the other benefits of recycling your scrap metal:

Energy Conservation

Recycling metal allows for the conservation of energy that would otherwise be used for more metal manufacturing needs. Different amounts of energy are used to process metals, but recycling something like steel can amount to 60 percent less energy than starting with raw materials, and aluminum saves an impressive 95 percent energy.

Creating More Jobs

When you opt to recycle your leftover metal material, you are employing one million or more workers in this field. There is a need for more employees than if you were having scrap incinerated and disposed of. We all know that the creation of domestic jobs is incredibly important right now.

Earning Additional Money

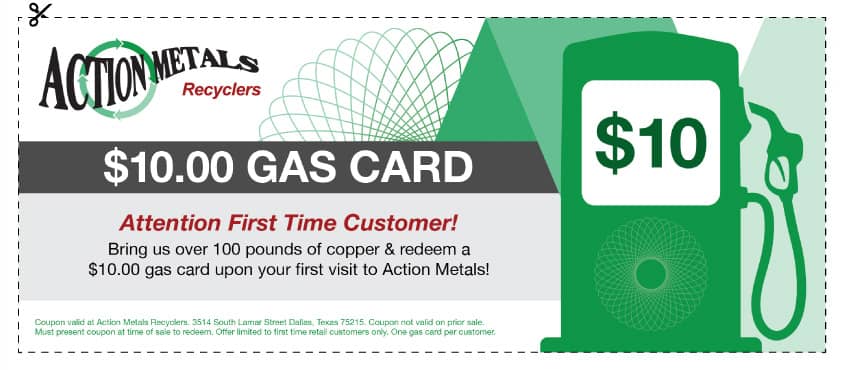

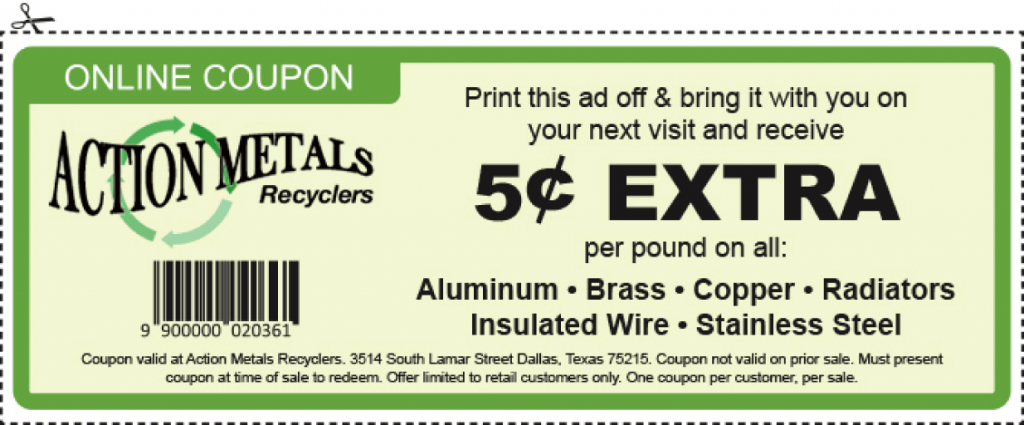

Many different scrap yards and recycling companies will accept metals such as brass, aluminum, iron, copper, and steel in exchange for a monetary payment. The amount you can make will vary from one Dallas metal recyclers company to another, and the current price for those metals. Typically, it’s common for non-ferrous metals to be worth a bit more money than ferrous metals.

Let’s take a look at some of the ways that you can streamline the process of recycling scrap metal for manufacturing plants.

Collection of Your Scrap

It helps if you have some sort of location on site where you will collect all of your scrap metal. This could be anything from a rented collection bin to some sort of container you’ve come up with on your own.

This is where employees will know to drop scrap so it can then be sorted, picked up, etc. Not only will this help to streamline the process of scrap metal recycling, but it can also help keep your plant safer, cleaner, and more organized.

Sorting Your Scrap

The most common way to sort your scrap is to separate it into ferrous and non-ferrous materials. Examples of ferrous materials would be iron or steel. Non-ferrous items would be brass, aluminum, copper, or stainless steel.

While you could allow another company to sort your scrap for you after receiving it, it can be faster to simply drop your material into different bins before pick up. This could also get you a discount of some sort, depending on where your scrap is going.

Scheduling a Pickup Ahead

Have your scrap picked up from your work site to eliminate the need for transporting it yourself.

You can usually work with a company to schedule a periodic pickup day/time so that all of your material is removed regularly. You can change the pickup frequency as needed.

Make Scrap Metal Recycling Easier Today with Action Metals Recyclers

If you want more information on how to streamline scrap metal recycling for your manufacturing plant, contact us at Action Metals Recyclers.

We can help you make the most out of your recycling efforts by way of environmental preservation, easy income from scrap sales, reduced industry prices on parts and so much more.